5 Essential Safety Rules to Minimize Risks in Industrial Workplaces

Workplace accidents in industrial factories consistently rank among the top five causes of occupational fatalities, second only to the construction industry. For those working in factories or warehouses, it is well understood that "danger can strike at any moment." The primary causes often stem from a lack of awareness, carelessness, or equipment failure. However, by following these "5 Essential Safety Rules", you can significantly enhance workplace safety and reduce the risk of accidents—for yourself and those around you.

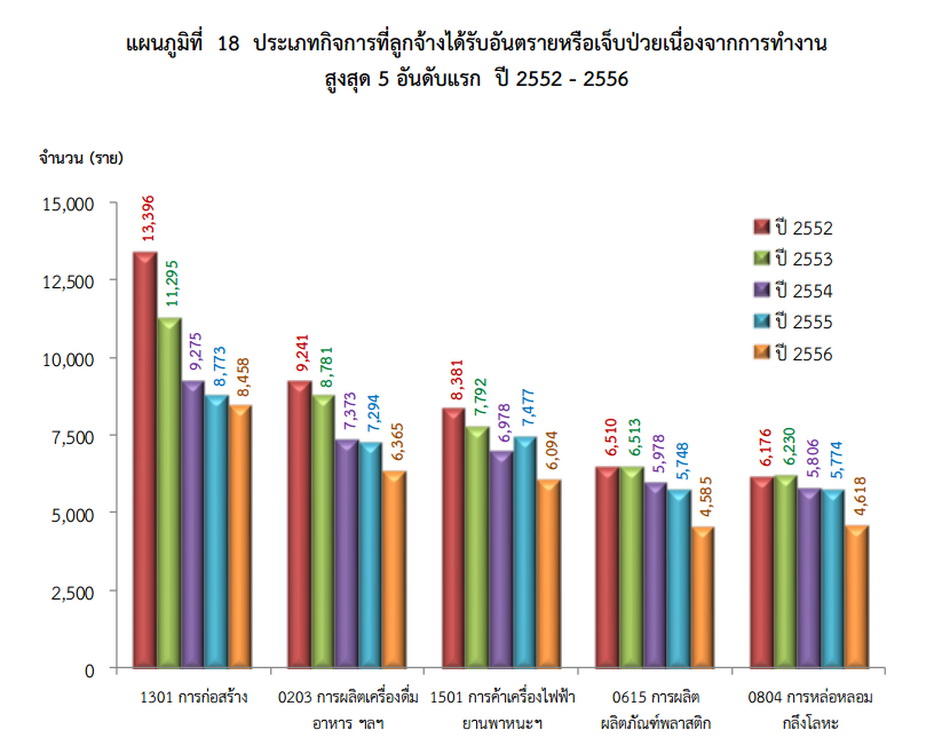

Workplace Injury and Illness Statistics according to data from the Social Security Office of Thailand

Let us explore these five crucial safety rules:

Rule 1: Know the Nature of Your Work and Its Associated Hazards

Gain a clear understanding of the tasks and operational processes involved in your work. Identify potential hazards in advance and prepare appropriate preventive measures to address them.

Rule 2: Know How to Select the Right Tools, Machinery, and Equipment

Before using any machinery or tools, ensure you understand which equipment is suitable for specific tasks and which are not. Just as you wouldn’t use a ruler to measure an entire room—instead opting for a tape measure—the same principle applies to selecting the correct tools. Even tools of the same type can serve different purposes.

Rule 3: Know How to Properly Use Tools, Machinery, and Equipment

Improper use of tools or machinery-especially those requiring skill-can pose serious dangers to both the user and others nearby. It is essential to understand how to operate them correctly. For example, if a ladder is rated for 120 kg, it should not be used by two individuals carrying heavy items at the same time. These weight limits already include a safety margin.

Rule 4: Know the Limitations of Tools, Machinery, and Equipment

Beyond knowing how to choose and use equipment, it’s equally important to understand their load limits and specifications. For instance, forklifts have maximum load capacities that must be respected. Additionally, some equipment—such as adjustable Micro Racks—can be extended or reconfigured for convenience, but their weight-bearing capacity must always be considered.

Rule 5: Know How to Maintain Tools, Machinery, and Equipment

Comprehensive knowledge of your tools and machines is incomplete without proper maintenance. Regular upkeep ensures that equipment remains in good working condition, operates safely, and reduces the frequency and cost of repairs. For example, daily forklift maintenance helps extend its lifespan and delay wear and tear.

The commercial, including articles and artworks shown is an intellectual property of Jenbunjerd Co.,Ltd. Unauthorized reproduction is prohibited and may subject to criminal prosecution.